Rexroad’s Retail Tips: How much should I buy?

Thanks for coming back for another healthy dose of retail best practices! Today, we’re venturing into Material Requirements Planning (MRP). This is a critical principle of procurement and can reduce your financial risks. MRP in retail often requires quite a bit of cash, which can make owners nervous. Let’s ease the tension by planning our stock keeping unit (SKU) levels with a thoughtful approach that justifies investments.

Decoding Material Requirements Planning (MRP)

Forget empty shelves and overflowing backrooms. MRP ensures you have just the right amount of inventory–not too little, not too much. But it’s more than a math problem. It’s a strategic approach for maintaining the perfect balance of inventory. It answers critical business questions, such as:

- How often do I want to order?

- How much purchasing power do I have?

- How much of this product do I expect to sell on average daily (a.k.a. Sales Velocity)?

- Have I met the consumer demand for this product, or did we have stockouts?

- How long does it take for me to receive the order?

- How long will it take for me to get this order approved?

Step-by-Step MRP: A Practical Guide

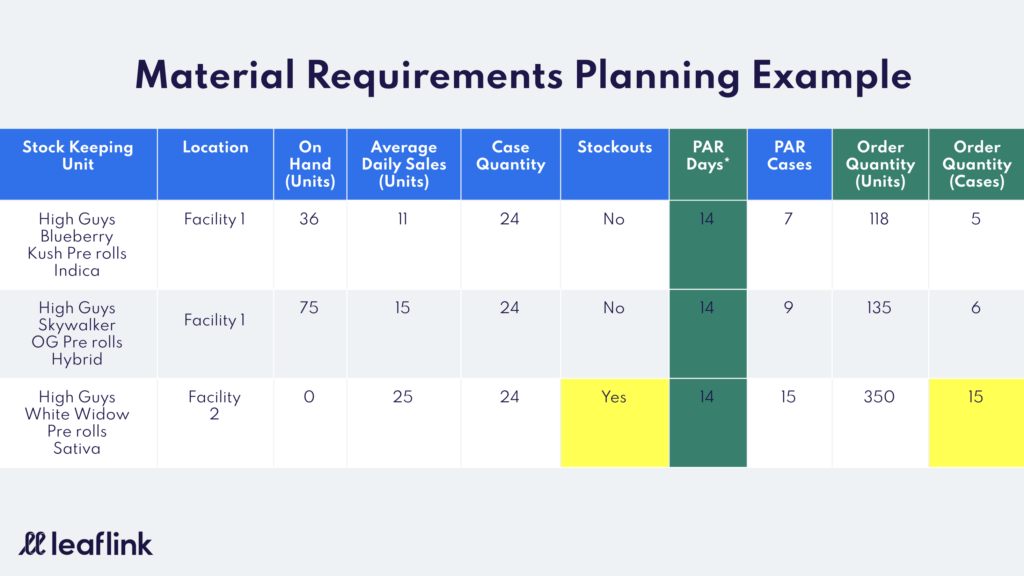

Let’s test drive MRP with a realistic scenario. Say we’re a buyer in legal-town, USA, tasked with stocking a single dispensary with High Guys pre-rolls. The following table is a basic MRP sheet which can successfully guide a buyer through a store-by-store, MRP calculation:

For every SKU and Location, the sheet details:

1. How many units the store has on hand

2. How many units are expected to be sold or depleted from the system daily

3. The case quantity

4. Whether or not we have experienced a stockout in the period

5. PAR days calculation

6. PAR units

7. Calculated order quantities

Tips for creating your plan:

- Ensure your On-Hand Inventory is Accurate: It’s easy to fall into the trap of trusting a number on a spreadsheet. Don’t do it! Take the time to ensure your on-hand inventory is regularly audited and reliable. Consider using inventory data from an up-to-date source such as METRC or your Point of Sale (POS) System.

- Assess Sales Velocity: Predicting demand comes down to three key ingredients: your current inventory, average daily sales, and case quantities. While historical averages offer a decent roadmap, savvy forecasters wield powerful algorithms like the weighted average. This champion algorithm balances past performance with recent sales trends, giving more weight to the hottest selling period. The result? A precise picture of upcoming sales ebbs and flows, guiding you to optimal inventory levels and avoiding stock outs or costly overstocking. For extra credit, examine last year’s results and compare. Seasonal trends can be captured by looking forward in time and observing the ebbs and flows of specific categories. Every product and category has a rhythm waiting to be discovered!

- Observe known stockouts. If a product has stocked out recently, you may underestimate the SKU’s full sales potential. Try adding an additional case in the next order cycle to stave off stock outs while refining your baseline demand measurement.

While addressing immediate stockouts is crucial, anticipating future demand based on data helps prevent them entirely. This is where PAR, or Periodic Automated Replenishment, comes into play.

PAR for the Course

PAR is a level of inventory that triggers inventory repurchasing with enough time and quantity to keep the item in stock, given its retail environment.

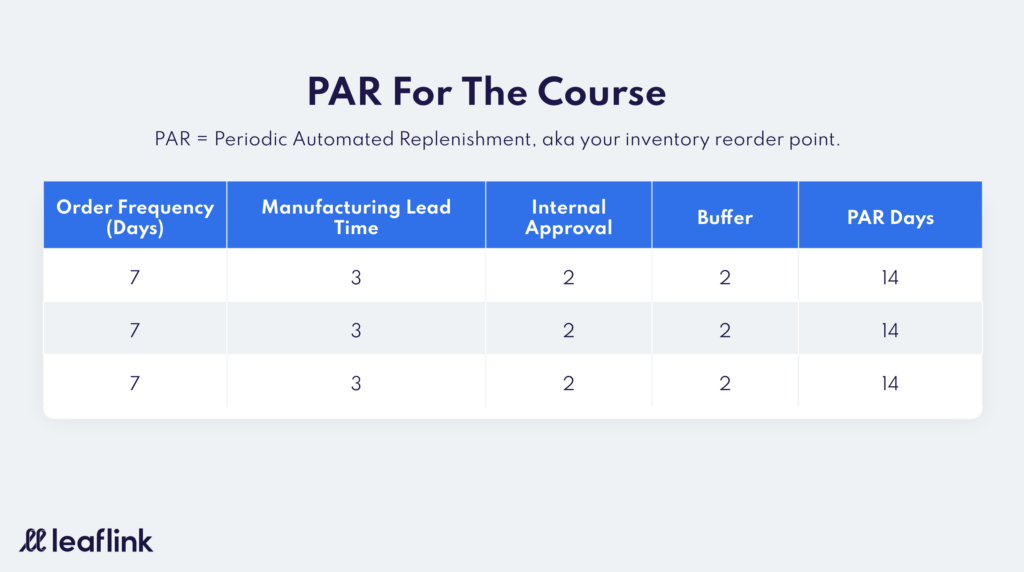

Imagine a buyer, constantly juggling daily sales and delivery lead times. They want enough pre-rolls to last until the next refill (their weekly cycle), which means keeping seven days worth of inventory on hand. But there’s a catch: They need to factor in approval time from the manufacturer and add a couple of extra days of “buffer time” in case of hiccups. That’s how we arrive at their reorder point: 14 days worth of inventory, ensuring a smooth flow without ever running dry. PAR Days can be adjusted and managed in various ways. They are often set to fit any location’s unique circumstances, including storage space, budget, approval methodology, and location.

For this example, we calculate PAR Days at 14 (two weeks) using the following methodology:

Calculating PAR Quantities

By taking our daily demand forecast (Average Daily Sales in this scenario) multiplied by our PAR Days, we arrive at the number of units expected to be sold during the time it takes us to place the order and restock it, represented as PAR Units. The resulting reorder quantity can then be converted to PAR Cases, for ordering case quantities. Finally, we subtract the units from the current number on hand and round up to the nearest entire case to arrive at our desired Order Quantity.

As product velocity changes over time, recalculate the PAR as often as you plan to order. A stale PAR level can lead to stockouts or overstocks if left unchecked. In our earlier example, you can see we experienced stock outs on one of the SKUs. It could be a sign that we haven’t yet realized the full sales potential of this product. Imagine all those extra units we could have sold if they hadn’t vanished from the shelves!

Here’s what I recommend:

- Test the Waters with an Extra Case: Add an additional case to the next replenishment order for this SKU. It’s like sending out a little sales detective to uncover the true demand. If those extra units fly off the shelves, we’ll know we were onto something.

- Full Steam Ahead (Unless…): Unless it’s a limited-time-only item or we’re strategically creating some scarcity for marketing purposes, it’s wise to keep our doors open for customers seeking this product. After all, they took the time to walk through the door, and we don’t want to disappoint them by not having what they want (and potentially send them to a competitor).

Remember, every stockout is a missed revenue opportunity. By strategically responding to these situations, we can optimize our inventory, boost sales, and keep our customers happy. It’s a win-win-win.

Weekly Rituals and Continuous Improvement

MRP isn’t a one-and-done deal; it’s a continuous cycle and an essential motion for a proper Category Management practice. The above practice should be done for every product your dispensary plans to sell and analyzed for seasonal adjustments with lead time specific to the seller’s ability to provide. Perform this analysis weekly, or even more frequently during peak seasons. It’s about being agile and responsive to market changes.

Using a distribution center? While the basic principles remain the same, managing inventory for multiple locations adds a layer of complexity, regardless of whether products arrive directly or through a central hub. The key is in thoroughly understanding SKU-level demand at each individual store before consolidating that data into a central picture.

Each new stop in the supply chain, like a distribution center, adds lead time considerations, but the effort can reap significant rewards. Imagine the power of leveraging economies of scale across your entire network! We’ll delve deeper into this multi-location magic in a future discussion.

With this and all retail solutions, adopting specific technology can reduce errors and save time. If you are working through a problem with your retail solutions, as always, consider LeafLink your ally!

Keep Learning With Rexroad’s Retail Tips

Choosing brands that bring in the fans (The Rexroad Method for Retail Assortment Optimization)

How much should I spend on inventory? (The Open To Buy Strategy)